Dealing With Rust And Corrosion: Prevention And Treatment

To prevent and treat rust and corrosion, use non-corrosive metals, keep surfaces clean and dry, and apply protective coatings like grease, oil, paint, or carbon fiber. These cost-effective methods help to prevent the damaging effects of rust and corrosion on metal surfaces.

By using metals like stainless steel or aluminum, ensuring cleanliness and dryness, and implementing protective coatings, you can effectively prevent and treat rust and corrosion. These measures help to extend the lifespan of metal objects and maintain their appearance and functionality.

Understanding Rust And Corrosion

Prevent and treat rust and corrosion by using non-corrosive metals like stainless steel, keeping surfaces dry and clean, applying coatings such as grease or paint, and using drying agents. These cost-effective methods help protect against the damaging effects of rust and corrosion.

What Is Rust?

- Rust is a natural process that occurs when metal reacts with oxygen and moisture in the air.

- It is a reddish-brown substance that forms on the surface of metal objects.

- Rust is a form of corrosion that weakens and destroys metal over time.

How Does Rust Form?

- Rust forms when metal is exposed to oxygen and moisture.

- The presence of water is essential for rust to occur because it enables the metal to act as an electrode.

- Oxygen reacts with the metal to form iron oxide, which is rust.

The Process Of Corrosion

- Corrosion is the gradual degradation of a metal due to chemical reactions.

- When metal corrodes, it loses its structural integrity and becomes weaker.

- Corrosion can occur due to various factors, including exposure to moisture, salt, acids, and atmospheric pollutants.

Key Factors That Contribute To Rust And Corrosion

- Moisture: The presence of moisture accelerates the corrosion process by providing an electrolyte for the chemical reactions.

- Oxygen: Oxygen reacts with the metal and initiates the corrosion process.

- Salt: Salt, particularly in coastal areas, increases the rate of corrosion. The salt acts as a catalyst for the chemical reactions.

- PH level: Acidic or alkaline environments can speed up the corrosion process.

- Temperature: Higher temperatures can accelerate the corrosion process.

- Pollution: Atmospheric pollutants can contribute to corrosion by reacting with metal surfaces.

Understanding the basics of rust and corrosion is crucial for effectively preventing and treating them. Rust occurs when metal reacts with oxygen and moisture, forming a reddish-brown substance known as rust. Corrosion is a gradual degradation of metal caused by chemical reactions.

Factors such as moisture, oxygen, salt, pH level, temperature, and pollution contribute to rust and corrosion. By understanding these factors, you can take proactive steps to prevent and treat rust and corrosion.

Prevention Methods

Preventing rust and corrosion involves using non-corrosive metals, keeping surfaces clean and dry, and applying protective coatings like grease, oil, paint, or carbon fiber. These cost-effective methods help prolong the lifespan of metal and prevent damage.

Selecting Non-Corrosive Materials:

- Use stainless steel materials: Stainless steel is known for its corrosion resistance, making it an excellent choice for preventing rust and corrosion.

- Opt for galvanized materials: Galvanization involves coating steel with a layer of zinc, which provides a protective barrier against rust and corrosion.

- Consider plastic or composite materials: Plastic and composite materials are often resistant to rust and corrosion, making them ideal for environments where moisture is present.

Protective Coatings And Paints:

- Apply anti-corrosion coatings: Anti-corrosion coatings act as a barrier between the metal surface and the surrounding environment, preventing rust and corrosion.

- Use epoxy paint: Epoxy paint is known for its excellent adhesion and high resistance to corrosion, making it an effective choice for protecting metal surfaces.

- Consider zinc-rich coatings: Zinc-rich coatings provide an added layer of protection by sacrificially corroding before the underlying metal does.

Maintaining Proper Cleaning And Drying Techniques:

- Clean surfaces regularly: Regular cleaning removes dirt and contaminants that can cause corrosion.

- Dry thoroughly: Ensure that surfaces are completely dry after cleaning to prevent moisture buildup, which can lead to rust and corrosion.

- Use appropriate cleaning agents: Use non-corrosive cleaning agents to avoid damaging the surface being cleaned.

Implementing Effective Ventilation Systems:

- Provide adequate airflow: Proper ventilation helps to reduce moisture levels and humidity, which are key factors in the development of rust and corrosion.

- Install exhaust fans: Exhaust fans help to remove moisture-laden air from enclosed spaces, reducing the risk of corrosion.

- Use dehumidifiers: Dehumidifiers can help control humidity levels, particularly in areas prone to high moisture, such as basements and crawl spaces.

Utilizing Rust Inhibitors And Protectants:

- Apply rust inhibitors: Rust inhibitors are chemicals that can be applied to metal surfaces to prevent or slow down the formation of rust.

- Use protective coatings or films: Protective coatings or films provide a barrier between the metal surface and the environment, preventing rust and corrosion.

- Consider using desiccants: Desiccants are substances that absorb moisture from the air, helping to keep the surrounding environment dry and reducing the risk of corrosion.

Remember, by implementing these prevention methods, you can effectively protect your belongings and structures from rust and corrosion. Selecting non-corrosive materials, applying protective coatings and paint, maintaining proper cleaning and drying techniques, implementing effective ventilation systems, and utilizing rust inhibitors and protectants are all essential steps in preventing rust and corrosion.

Treatment Options

When dealing with rust and corrosion, prevention and treatment options are crucial. Methods such as using non-corrosive metals, keeping surfaces clean and dry, and applying protective coatings like grease or paint can effectively combat rust and corrosion.

When it comes to dealing with rust and corrosion, prevention is always better than treatment. However, if you find yourself faced with rust damage, there are several treatment options available to help you combat the problem. Here are some effective methods for treating rust and corrosion:

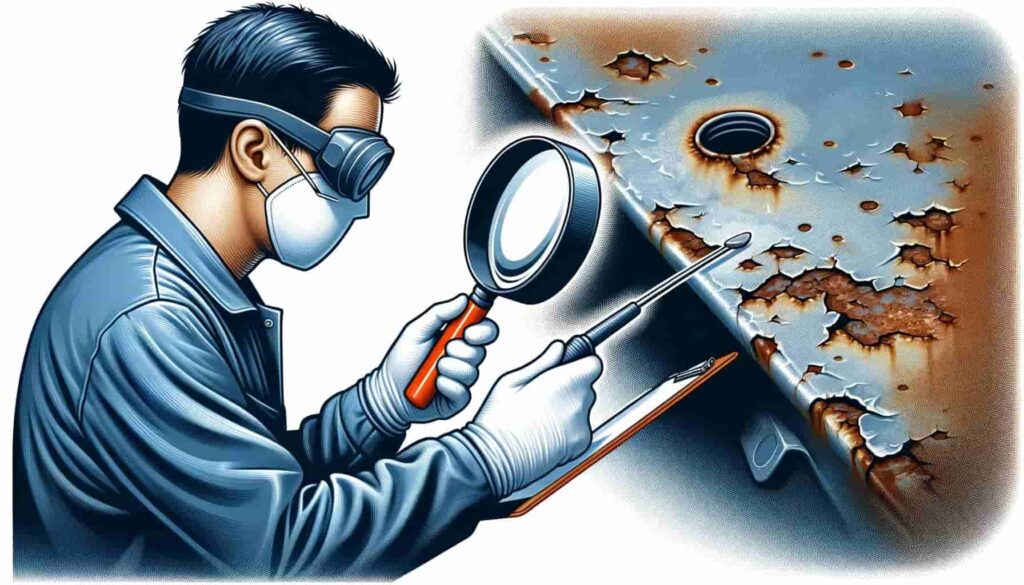

Inspection And Assessment Of Rust Damage:

- Thoroughly inspect the affected area to assess the extent of the rust damage.

- Look for signs of corrosion, such as discoloration, pitting, or flaking.

- Determine whether the rust is superficial or if it has penetrated the metal surface.

- Assess the structural integrity of the corroded object.

Mechanical Removal Of Rust:

- Use abrasive tools like wire brushes, sandpaper, or sandblasting to physically remove rust from the surface.

- Apply gentle pressure while scrubbing to avoid damaging the underlying metal.

- Regularly clean the working surface of the tool to prevent the re-deposition of loose rust particles.

Chemical Treatments For Rust Removal:

- Use rust dissolvers or rust removal sprays that contain chemicals like phosphoric acid, citric acid, or oxalic acid.

- Apply the chemical treatment to the rusted area according to the manufacturer’s instructions.

- Give the chemicals enough time to penetrate and dissolve the rust.

- Use a wire brush or cloth to scrub away loosened rust particles after the treatment.

Application Of Rust Converters And Primers:

- Apply rust converters, which contain tannic acid or phosphoric acid, to chemically convert rust into a stable compound.

- Once the rust has been converted, apply a primer specifically designed for rusty surfaces.

- Primers create a protective barrier that prevents further rust formation and provides a smooth base for paint application.

Use Of Protective Coatings And Sealants:

- Apply protective coatings like enamel, epoxy, or polyurethane paint to prevent access to moisture and oxygen, which are essential for rust formation.

- Use sealants, such as silicone or epoxy-based sealants, to fill any gaps or cracks that could allow moisture to seep in and accelerate corrosion.

By following these treatment options, you can effectively combat rust and corrosion and prolong the life of your metal objects. Remember, regular inspection and maintenance are key to preventing severe rust damage and costly repairs.

Credit: www.rac.co.uk

Best Practices For Rust Prevention

Learn the best practices for rust prevention in dealing with rust and corrosion. Discover cost-effective methods such as using non-corrosive metals, keeping surfaces clean and dry, and utilizing protective coatings like grease, oil, or paint. Avoid the damaging effects of rust with these preventive measures.

Regular maintenance and inspections:

- Conduct regular inspections to identify any signs of rust or corrosion.

- Look for any areas where paint has chipped or peeled, as these are prone to rust.

- Perform routine maintenance tasks such as cleaning and lubricating to prevent rust from forming.

Proper storage techniques:

- Store metal items in a dry environment, away from moisture and humidity.

- Use moisture-absorbing materials, such as silica gel packs or desiccant bags, to reduce humidity in storage areas.

- Consider using plastic or rubber containers to store metal items, as they provide a barrier against moisture.

Addressing moisture issues:

- Keep metal surfaces dry by wiping off any moisture immediately.

- Use rust inhibitors or protective coatings on metal surfaces to prevent moisture from reaching the metal.

- Install dehumidifiers or ventilation systems in areas prone to high humidity to reduce moisture levels.

Rust prevention in specific environments:

- Marine: Use marine-grade paints and coatings that are specifically designed to withstand the corrosive effects of saltwater.

- Automotive: Regularly wash and wax your vehicle to protect the paintwork and prevent rust formation.

- Industrial: Apply corrosion-resistant coatings or paints to metal surfaces in industrial settings to protect against rust and corrosion.

Diy Home Remedies For Rust Prevention

Discover effective DIY home remedies for rust prevention and corrosion treatment. Learn how to use non-corrosive metals, maintain a clean and dry surface, apply protective coatings like grease or paint, and more to protect your belongings from rust and corrosion.

Vinegar And Baking Soda Paste:

- Create a paste by mixing equal parts vinegar and baking soda in a bowl.

- Apply the paste to rusty areas using a brush or cloth.

- Leave the paste on for at least 30 minutes to allow the solution to work on the rust.

- Scrub the rusted surface using a brush or scrubber to remove the rust.

- Rinse the area with clean water and dry thoroughly.

- Repeat the process if necessary to fully remove the rust and prevent further corrosion.

Lemon And Salt Solution:

- Squeeze the juice of a lemon into a bowl and add a generous amount of salt.

- Mix the lemon juice and salt to form a solution.

- Apply the solution to rusty surfaces using a cloth or sponge.

- Let the solution sit on the rusted area for about 1 hour.

- Scrub the rusted surface using a brush or scrubber to remove the rust.

- Rinse the area with clean water and dry thoroughly.

- Repeat the process if needed to completely remove the rust and prevent future corrosion.

Petroleum Jelly Application:

- Clean the rusted area with a cloth or sponge to remove any dirt or debris.

- Apply a thick layer of petroleum jelly to the rusty surface.

- Let the petroleum jelly sit on the rusted area overnight.

- Use a soft cloth or sponge to wipe away the petroleum jelly.

- Scrub the rusted surface gently using a brush or scrubber to remove any remaining rust.

- Rinse the area with clean water and dry thoroughly.

- Reapply petroleum jelly as necessary to prevent further rust and corrosion.

Using Rust Prevention Sprays:

- Choose a rust prevention spray suitable for the type of metal you want to protect.

- Shake the rust prevention spray well before using.

- Hold the can about 6-8 inches away from the metal surface.

- Spray a thin and even layer of rust-prevention spray onto the surface.

- Allow the spray to dry completely according to the instructions on the can.

- Repeat the process periodically to maintain rust protection.

- Rust prevention sprays create a protective barrier that prevents rust and corrosion.

Professional Services For Rust Treatment

Our professional services for rust treatment provide effective solutions to prevent and treat rust and corrosion. With expertise in dealing with rust and corrosion, we offer tailored treatments and prevention methods to protect your assets.

Rust and corrosion can cause significant damage to your belongings, structures, and equipment. If you’re dealing with rust issues, it’s essential to seek professional services for proper treatment. Corrosion control companies specialize in providing effective solutions to prevent and treat rust.

Here are some of the services offered by these companies:

- Electrochemical treatments: Corrosion control companies use electrochemical methods to remove rust and restore metal surfaces. This process involves the application of a low-voltage electrical current through the metal, which helps in reversing the corrosion process.

- Sandblasting and abrasive methods: Corrosion control companies also offer sandblasting and abrasive methods to remove rust from surfaces. These techniques involve using high-pressure air or water mixed with abrasive materials to eliminate rust and prepare the surface for further treatment.

- Long-term protective coatings and systems: To prevent future rusting and corrosion, corrosion control companies provide long-term protective coatings and systems. These coatings act as a barrier between the metal surface and the corrosive environment, ensuring extended protection.

By availing the services of a corrosion control company, you can effectively treat and prevent rust, preserving the longevity and durability of your belongings, structures, and equipment.

Importance Of Regular Maintenance In Rust Prevention

Regular maintenance plays a crucial role in preventing rust and corrosion. By using non-corrosive metals, keeping surfaces clean and dry, and applying protective coatings, such as paint or grease, you can effectively reduce the risk of rust formation and prolong the lifespan of your equipment.

The Benefits Of Proactive Maintenance:

- Regular maintenance is crucial for preventing rust and corrosion, as it allows for early detection and treatment of any signs of damage.

- Proactive maintenance helps extend the lifespan of your equipment, saving you money on costly repairs and replacements.

- By conducting regular inspections and maintenance, you can identify potential problem areas and take preventive measures to avoid rust and corrosion.

- Avoiding rust and corrosion also ensures the optimal performance and efficiency of your equipment, reducing downtime and improving productivity.

Monitoring And Addressing Early Signs Of Rust:

- Regular monitoring of your equipment allows you to identify early signs of rust and corrosion, such as discoloration, pitting, or flaking.

- Once you notice any signs of rust, it’s essential to address them immediately to prevent further damage and deterioration.

- Cleaning the affected area and applying rust inhibitors can help stop the spread of corrosion and protect the surrounding surfaces.

- It’s important to take a proactive approach in monitoring and addressing early signs of rust to minimize the risk of extensive damage and costly repairs.

Developing A Preventive Maintenance Plan:

- Creating a preventive maintenance plan is crucial in rust prevention, as it helps you stay organized and systematic in your maintenance efforts.

- Start by identifying the equipment and surfaces that are prone to rust and corrosion, and prioritize them in your maintenance schedule.

- Implementing regular cleaning, lubrication, and rust protection measures in your maintenance plan can significantly reduce the risk of rust formation.

- Keep track of maintenance activities, log any issues or repairs, and schedule regular inspections to ensure the effectiveness of your preventive measures.

Remember, regular maintenance plays a vital role in preventing rust and corrosion. By being proactive in your approach, monitoring early signs of rust, and developing a preventive maintenance plan, you can protect your equipment, extend its lifespan, and avoid costly repairs.

Frequently Asked Questions On Dealing With Rust And Corrosion: Prevention And Treatment

What Are Three Methods Of Corrosion Prevention?

Three methods of corrosion prevention include using non-corrosive metals, keeping the metal surface clean and dry, and applying a coating or barrier product such as grease, oil, paint, or carbon fiber coating.

Which Is The Best Method To Prevent Rusting?

Galvanization is the best method to prevent rusting.

What Is Treatment For Rusting?

The best method to prevent rusting is galvanization.

How Do You Deal With Corrosion?

To deal with corrosion, you can use non-corrosive metals, keep the surface clean and dry, use drying agents, or apply a coating like grease, oil, paint, or carbon fiber. Galvanization is the best method to prevent rusting.

Conclusion

Preventing rust and corrosion is essential for preserving the longevity of metallic objects. By following a few simple steps, you can ensure that your belongings remain in top-notch condition. Firstly, opt for non-corrosive metals like stainless steel or aluminum, as they are less likely to rust.

Secondly, maintaining a clean and dry metal surface is crucial in preventing corrosion. Using drying agents can facilitate this process. Additionally, applying a protective coating or barrier product such as grease, oil, paint, or carbon fiber can create an added layer of protection.

Galvanization, which involves covering the metal with a layer of zinc, is widely regarded as the best method to prevent rusting. By implementing these preventive measures, you can significantly reduce the occurrence of rust and corrosion, saving both time and money in the long run.

Preserve your belongings and ensure their durability by taking the necessary steps to prevent rust and corrosion. “