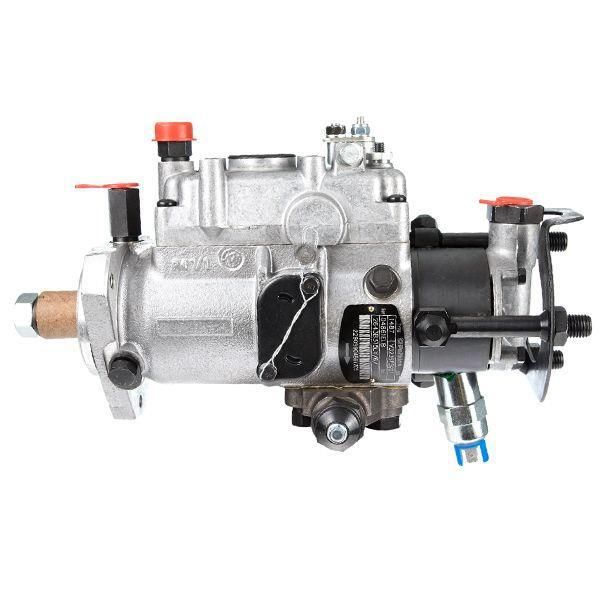

Perkins 3 Cylinder Diesel Injector Pump Diagram

The Perkins 3 Cylinder Diesel Injector Pump Diagram is a visual representation of the fuel injection system in a Perkins 3 cylinder diesel engine. It shows the various components and their connections, including the injection pump, fuel lines, and injectors.

This diagram is useful for understanding the internal workings of the injector pump and troubleshooting any fuel delivery issues.

Common Problems And Causes Of Diesel Fuel Pump And Fuel Injector Issues

Dirty fuel and debris in the injector pump can cause common problems such as clogging of the spray tip. This is the section where fuel exits the injector and enters the combustion chamber. To identify a bad diesel fuel injection pump, look out for signs and symptoms such as engine misfires, decreased fuel efficiency, and difficulty starting the engine.

Diagnostic methods include performing a fuel pressure test and inspecting the pump for leaks or physical damage. If the pump is faulty, it can be repaired through injection pump rebuilding services. Some brands that offer pump repair services include Bosch and Delphi.

Understanding the pressure in a Perkins lift pump is crucial, as recommended pressure levels ensure proper functioning of the engine. Genuine Perkins fuel injection pumps can be purchased directly from Perkins, offering benefits such as hassle-free and fast delivery options.

To maintain Perkins fuel injection pumps, regular cleaning and inspection are recommended. Helpful resources such as websites, forums, reference materials, and guides can provide further information and diagrams for better understanding.

Credit: shop.perkins.com

Frequently Asked Questions Of Perkins 3 Cylinder Diesel Injector Pump Diagram

What Is The Common Problem In Injector Pump?

The common problem in the injector pump is dirty fuel that can lead to clogging, especially in the spray tip.

How Do I Know If My Diesel Injection Pump Is Bad?

Signs of a bad diesel injection pump include clogging, debris buildup, and fuel delivery issues.

What Is The Pressure On A Perkins Lift Pump?

The pressure on a Perkins lift pump varies depending on the specific model and application. It typically ranges from 3 to 10 psi.

Can Diesel Injector Pump Be Repaired?

Yes, diesel injector pumps can be repaired. Professional repair services can assess damages, replace worn parts, and reassemble the pump.

Conclusion

The Perkins 3 Cylinder Diesel Injector Pump Diagram provides valuable insights into the functioning of this important component in diesel engines. By understanding the inner workings of the injector pump, readers can gain a deeper appreciation for its role in the combustion process.

Dirty fuel is a common problem that can lead to clogging of the spray tip and other parts of the injector pump. Coastal Diesel Injection shares some of the common causes of diesel fuel pump and fuel injector problems, highlighting the importance of regular maintenance and cleaning.

In case of a bad diesel fuel injection pump, there are ways to identify the issue. This useful video on YouTube explains how to tell if you have a bad diesel fuel injection pump, providing step-by-step instructions for troubleshooting. If repair is necessary, Performance Diesel Injection offers complete rebuild services for various brands of injection pumps, including Bosch, Delphi, and Stanadyne.

They can assess the damages and replace any worn parts before reassembling the pump. For those seeking genuine and original fuel injection pumps for their Perkins engines, Perkins Engines offers hassle-free and fast service with free delivery and 28-day returns.

With a better understanding of the Perkins 3 Cylinder Diesel Injector Pump Diagram, diesel engine owners can ensure proper maintenance and efficient performance of their vehicles.